Reducing CO₂ Emissions Across the Entire Supply Chain with the GX Series Using Biomass Materials

The ENEOS Group, as a leading company in the energy and materials industries in Japan, is working alongside the government and other companies to achieve a carbon neutral society by 2050 using methods such as renewable energy, biomass, and CCS (CO₂ capture and storage technology). This time, we interviewed Hayashi Kenichiro of the Lubricants Sales Marketing Group, who is working to further reduce CO₂ emissions by promoting a circular economy through the conversion of materials. ENEOS is developing lubricant products using plant-derived base materials that contribute to reducing CO₂ emissions throughout the supply chain, including customer use. We will talk in detail about products with plant-derived base materials that still maintain the conventional performance of fuel efficiency and longer lubricant life.

Contents

What is the background behind your promotion of a switch to plant-derived base materials?

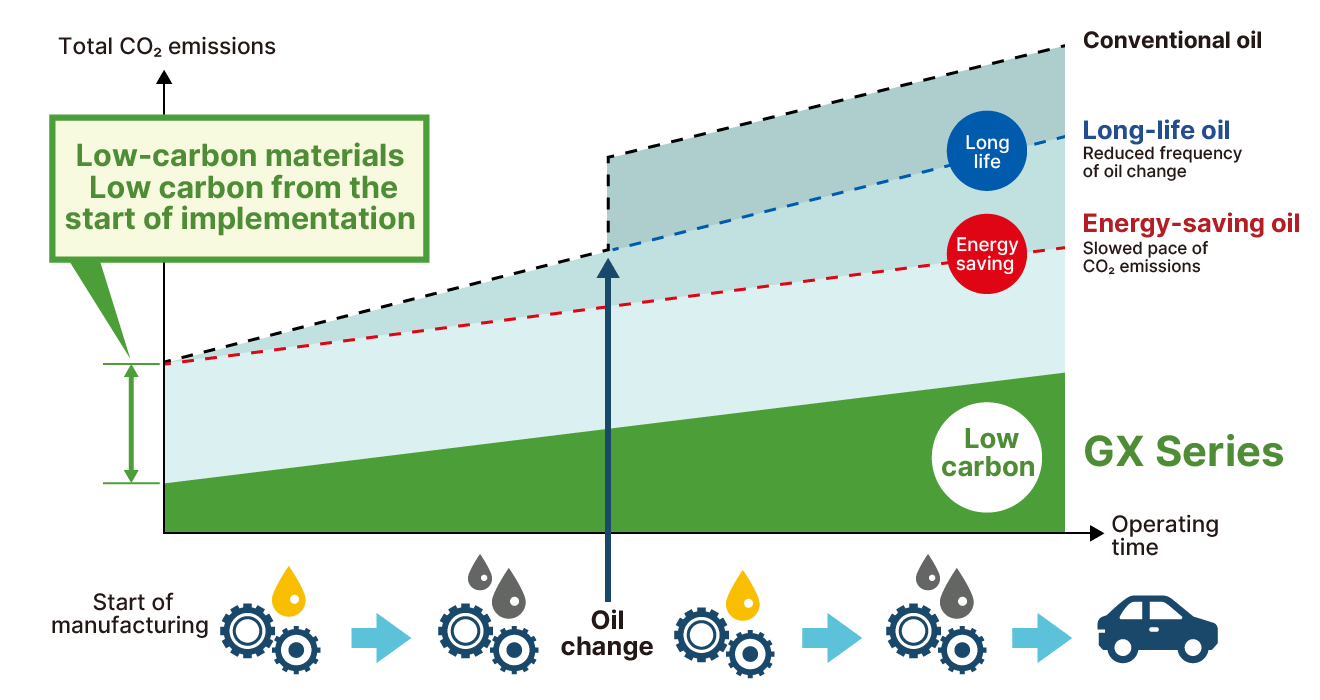

We have provided many products that help to save energy. As a new initiative, we have been working to develop lubricants that help to reduce CO₂ emissions during customer use by adopting low-carbon base materials such as plant-derived base oil. We have also listened to feedback from companies aiming to procure sustainable materials, thus resulting in the birth of the GX Series.

Approaches to CO₂ Emissions in Product Life Cycles and Corporate Supply Chains

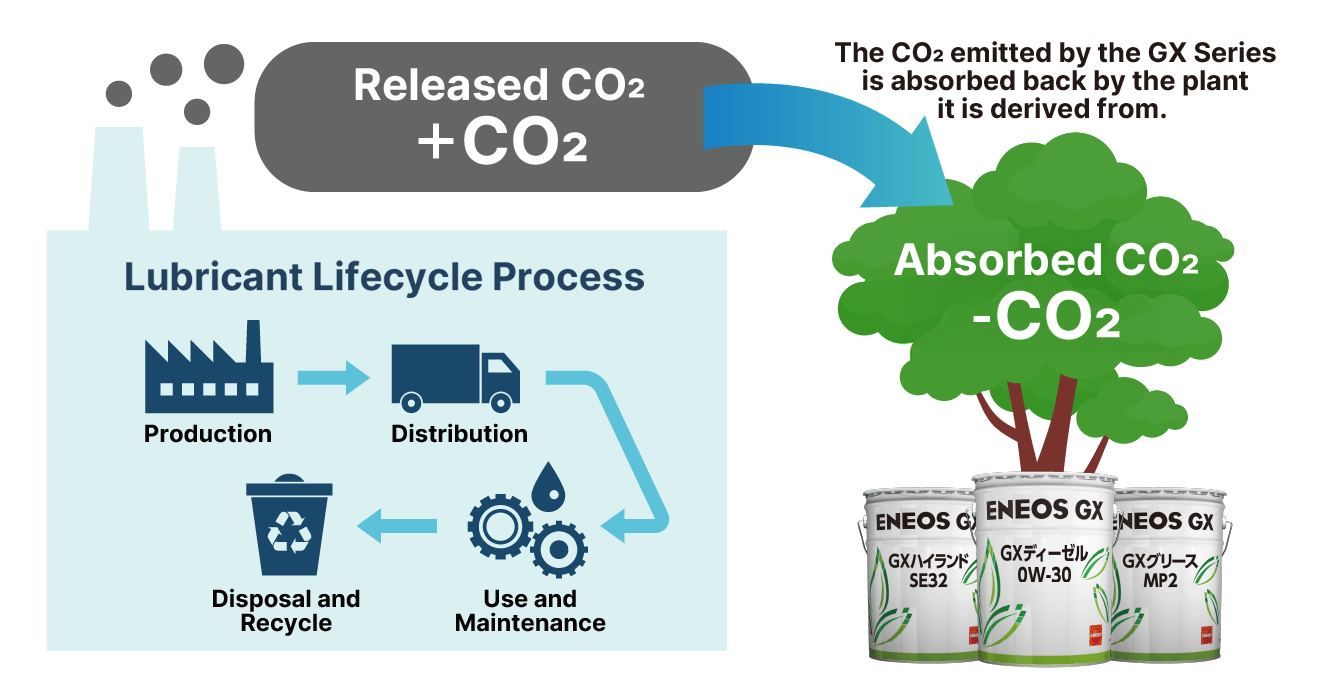

Supply chain CO₂ emissions are calculated by adding up not only the company's emissions, but also the emissions from each stage of the product life cycle.

・Scope 1: CO₂ emitted by the company during manufacturing, such as from fuel combustion

・Scope 2: CO₂ emitted indirectly by the company through the use of electricity and heat supplied by other companies

・Scope 3: CO₂ emitted by other companies in the supply chain, such as in the procurement of raw materials, transport, sales, and disposal

Source: Calculation Method for Supply Chain Emissions: Calculating Emissions - Green Value Chain Platform, Ministry of the Environment (env.go.jp)

The GX Series contribute to carbon neutrality by reducing emissions at the point of raw material procurement (Scope 3).

As the name suggests, lubricants are oils that lubricate and smooth things to reduce friction. Friction increases when gears or metal parts come into direct contact with each other. Using lubricants makes it possible to reduce friction, which in turn saves energy and helps to prevent metal wear and seizing. Thus, lubricants are essential for the transport and logistics industries (e.g. trucks, buses, taxis), the construction industry (e.g. heavy machinery, large vehicles), and the manufacturing industry (e.g. large machinery). However, 80% of lubricants use mineral oil, which is produced by refining crude oil, as their base oil.

What are the features of the GX Series?

GX Diesel 0W-30

GX Diesel 0W-30 is a lubricant mainly used in the diesel engines of commercial vehicles. It conforms to the JASO DH-2F standard and achieves high fuel economy while reducing CO₂ emissions by 4.16 tons per vehicle per year compared to JASO standard oil (*based on bench testing (JASO M362) results, annual mileage: 80,000km, CO₂ emission coefficient of diesel oil = 2.58). It also successfully extends the lubricant's lifespan, demonstrates high performance in terms of wear resistance and cleanliness, and inhibits the poisoning of exhaust gas reduction catalysts.

GX Highland SE32

GX Highland SE32 is an industrial hydraulic oil used in equipment such as plant machinery. It has the same performance as ENEOS's flagship energy-saving hydraulic oil, Super Highland SE32, and not only reduces CO₂ emissions, but also offers excellent energy-saving properties from its superior friction characteristics, long-lasting lubrication, and thermal stability. As a result, the amount of dirt and other types of sludge generated during machine operation is extremely low, and the oil can be used for longer periods of time under high temperatures and high pressure, thus reducing the frequency of oil changes.

GX Grease MP2

GX Grease MP2 has the same performance as ENEOS's conventional TOUGHLIX GREASE MP2, featuring power-saving and temperature-control effects for use in plants and other facilities. According to in-house research, it has an almost 25% power-saving effect compared to other products on the market, and also suppresses temperature increases by 10°C or more (*based on the results of in-house laboratory tests using ball bearings and room temperature). It contributes to carbon neutrality in terms of both the composition of the plant-derived base oil and its power-saving performance.

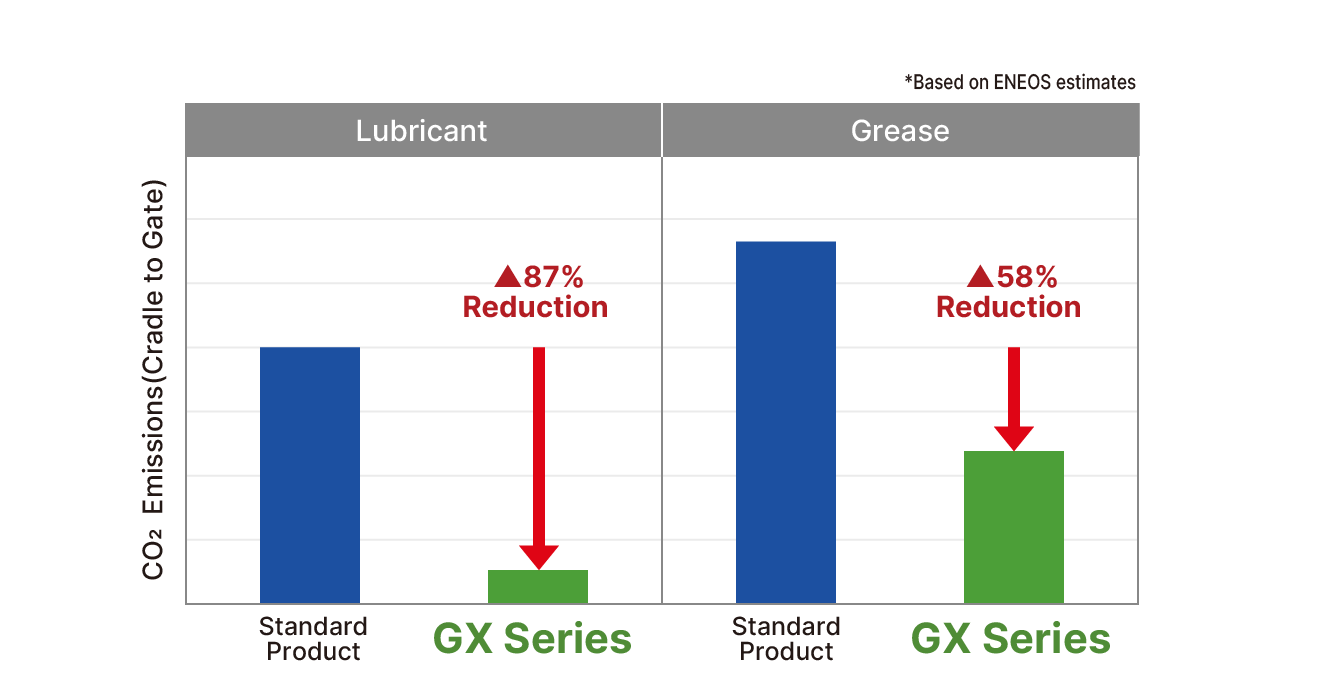

In addition to having the same performance as conventional products, these products have been proven to reduce CO₂ emissions during use, as shown in the following diagram.

GX Series: The base oil equivalent part of the reference products has been replaced with data for the biomass base oil used in these products.

What was the development process like for these products?

We began considering commercialization for the first time in 2021. ENEOS took note of a plant-derived base oil produced by a company in the United States (company name not disclosed). We realized that this base oil was carbon negative from cradle to gate. After conducting detailed research into the characteristics of the base oil and carrying out a series of tests to ensure the performance of the finished product, we succeeded in giving it biomass characteristics while maintaining the performance of the lubricants ENEOS has been providing. We were thus able to launch the products in 2023.

What challenges are you facing in further utilizing biomass raw materials?

The price range of the GX Series may seem high compared to products made from crude oil-derived base oils. However, I think the current challenge is having people understand the environmental value of CO₂ reduction at the point of purchase of lubricant products. If we can expand the demand for plant-derived raw materials, we can also expect to increase the supply of raw materials, thus leading to large-scale production and cost reductions. We also want to expand demand through feedback from customers in various industries and expanding our product lineup.

What are your future plans?

In addition to developing plant-derived lubricants, we are also conducting research into the recycle of used lubricants. We are working toward practical application through a process of collecting used lubricants, refining them at our plants, and then using them to make new lubricants. We expect that demand for lubricants that contribute to carbon neutrality will certainly increase in the future, so ENEOS will continue to accumulate know-how in order to meet this demand.