Green Chemicals: Taking on the Challenge of Creating Sustainable Plastic Raw Materials ~ About biochemicals and chemical recycling ~

- CES

- R&D

- ENEOS Central Technical Research Laboratory

- New Businesses

- Innovation

- Materials

- Circular economy

- Recycle

- sustainability

The ENEOS Group, as a leader in the energy and materials industry in Japan, aims to achieve a carbon-neutral society by 2050 by utilizing renewable energy, biomass, and carbon dioxide capture and storage (CCS). In this article, we talked to Hayashi Makoto from the Basic Chemicals Planning Department and Sato Kota from the Basic Chemicals Sales Department, who are promoting the defossilization of plastic raw materials (green chemicals). We will dive into two solutions: biochemicals that use plants, used oil, and such as raw materials for chemicals, and recycled chemicals that come from raw materials derived from the conversion of waste plastic into oil.

Contents

What is the green chemicals initiative about?

Traditionally, plastic products were produced from raw materials obtained through refining petroleum. Green chemicals are plastic products made from non-fossil raw materials, not used to be made from petroleum . ENEOS is working on the following two solutions in particular.

➀ Biochemicals that use biomass raw materials such as plants and used cooking oil

② Chemical recycling that converts waste plastic back into oil for use as resources

What are the needs for green chemicals by companies using plastic products?

While plastic is extremely convenient, there is the issue of emitting a lot of carbon dioxide during the process of manufacturing, usage, and disposal. In part due to recent trends such as carbon neutrality, many companies have stated targets regarding environmental consciousness. Specifically, companies that manufacture or use plastic products are promoting initiatives toward reducing the emission of CO2 in the life cycles of their plastic products as well as initiatives toward resource circulation. The green chemicals of ENEOS can contribute to this area. In fact, we are receiving a lot of feedback from many companies about their desire to use plastic made from raw materials derived from biomass or through recycling.

Can you tell us more about biochemicals and recycled chemicals?

For biochemicals, first, biomass raw materials such as plants and used cooking oil are hydrogenated to create petroleum-like oil (bio-derived chemical raw material). This is then processed in the same way as petroleum refining at a refinery to create plastic raw materials.

In 2023, ENEOS introduced bio-derived chemical raw materials made from used cooking oil and such to our Mizushima Refinery in Okayama Prefecture and manufactured bio-derived raw materials for PET bottles (bio-paraxylene). This was the first time in the world that bio-paraxylene was manufactured on a commercial scale. Suntory began introducing PET bottle using our bio-paraxylene for their select products in Japan.

We are studying the building of our own integrated system that manufacturing of bio-paraxylene made from feed stocks with used cooking oil and so on.

Chemical recycling is an initiative where various types of plastics—such as disposed packaging and containers—are broken down to the molecular level, changed into petroleum-like oil (recycling-derived chemical raw material), and then used to manufacture plastic raw materials through the process of petroleum refining.

ENEOS and Mitsubishi Chemical are currently undertaking joint construction of a facility to convert waste plastic into oil at the Kashima district of Ibaraki Prefecture, with the goal being to commence operation in fiscal 2025. When this facility is completed, it will be possible to convert approximately 20,000 tons of waste plastic back into oil each year.

Furthermore, seeking resource circulation for tires, we are conducting joint research and development with Bridgestone to convert used tires back into tires using chemical recycling.

What is the mass balance stated in press releases?

When non-fossil-derived raw materials—such as raw materials derived from biomass and recycling—are mixed with traditional raw materials derived from petroleum in the processing and distribution from raw materials to finished products, this method assigns the value of non-fossil raw materials—such as reduction of CO2 emissions—to a portion of the product in proportion to the input of non-fossil raw materials.

Large investments are needed to construct specialized equipment for manufacturing plastic raw materials using biochemicals or chemical recycling. Therefore, ENEOS proposes to customers the mass balance approach that allows the same quality as existing products to be provided through the use of existing equipment.

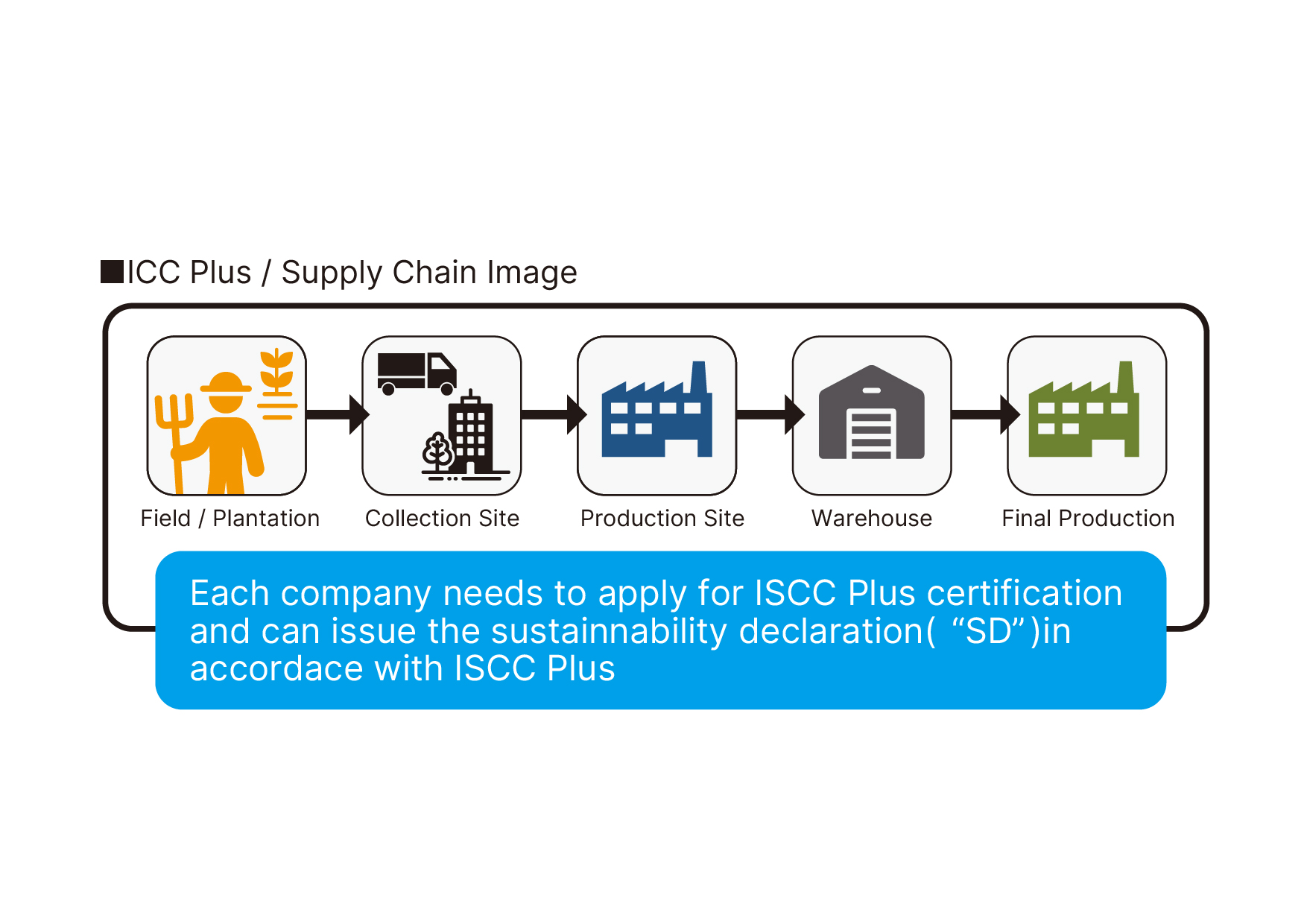

There is also the international certification system called ISCC PLUS that can be applied to mass balance products. Under this certification, third parties assure that the management of mass balance is properly carried out in the supply chain. ENEOS ensures the reliability and traceability of green chemicals that use the mass balance approach by obtaining this ISCC PLUS certification.

What are the future prospects for the green chemicals of ENEOS?

In our Carbon Neutrality Plan, one goal under the field of materials is to pursue a circular economy that circulates resources without relying on conventional resources such as petroleum. So far, it was a single direction whereby raw materials were made from petroleum, then consumed and disposed. Going forward, by turning waste plastic into plastic again and using biomass raw materials, we are aiming to realize a society that circulates resources without having to dig up new resources from underground.

Specifically, we seek to supply chemical materials using non-fossil raw materials for 20% by 2030. To achieve this target, we hope to collaborate with various partners and lead the expansion in use of green chemicals within and outside Japan.