ENEOS Receives Industrial Research Award of the Molecular Simulation Society of Japan at the Molecular Simulation Symposium!

Molecular simulation technology, developed as part of ENEOS Materials' R&D initiatives, has achieved significant results. The industry-academia collaboration team composed of Hatamiya Shintaro from ENEOS Holdings' AI Innovation Department, Matsumoto Shouichi from ENEOS Materials' R&D Headquarters and the Institute of Innovation for Future Society of Nagoya University received an Industrial Research Award of the Molecular Simulation Society of Japan in January 2025 for their highly-praised work on the Simulation in Stereoselective Polymerization of Butadiene. Molecular simulation technology is an advanced research field that reproduces molecular motion and reactions on computers, and it is a key component for accelerating development of ENEOS Materials' rubber products. We asked Matsumoto and Hatamiya about their research and the latest developments.

Contents

Various Rubber Products that Support Daily Life

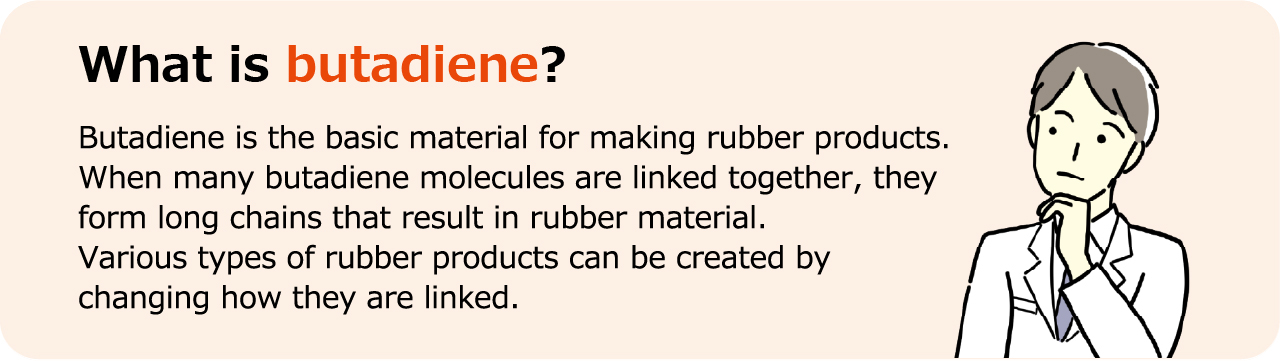

ENEOS Materials develops and manufactures a wide range of rubber products that support daily life. ENEOS Materials' technology is utilized in numerous rubber products found in every aspect of our surroundings, including abrasion resistant rubber for vehicle tires, highly safe rubber for medical devices, functional rubber used in battery materials, and special rubber for sports equipment and industrial machinery.

In developing such a wide range of rubber products, controlling the molecular structure derived from the raw material butadiene is key to product performance. That is why Matsumoto and Hatamiya focused on designing materials at the molecular level by utilizing the latest simulation technology.

The Importance of Molecular Design in the Development of Rubber Products

The key factor for determining the performance of rubber products is how the rubber molecules are bonded. The way molecules bond and arrange themselves significantly affects rubber properties such as hardness, strength, elasticity, and heat resistance. For example, when the molecular structures align regularly, it may become crystalline, which results in a harder rubber.

Catalysts are used to intentionally control such molecular structures. A catalyst is a substance that accelerates chemical reactions, and it acts as a kind of mediator, guiding how molecules bond without changing itself. Using a cooking analogy, just as the same ingredients can result in completely different flavors depending on the cooking method and seasoning, the same rubber raw materials can create rubber materials with entirely different properties based on the catalyst type and formula used.

ENEOS Materials aims to develop unprecedented, superior rubber materials by further pursuing the potential of this catalyst technology.

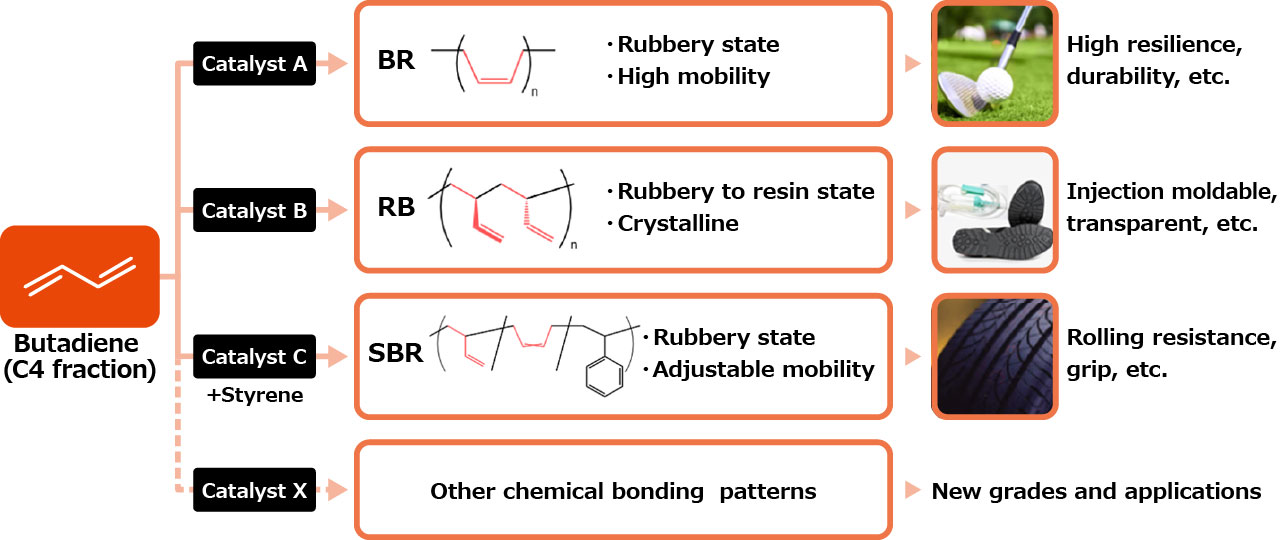

Catalyst Design Challenges in Research and Development

Catalysts are composed of multiple components, each performing a critical function. For example, they include a central metal compound (such as titanium or nickel) that drives the reaction, an organic ligand that controls molecular arrangement, a promoter that enhances reaction efficiency, and additives that improve catalyst stability. The challenge in catalyst development lies in finding the optimal combination of these components.

In conventional research and development processes, finding the optimal combination of these components required repeating numerous experiments. Matsumoto describes the challenges faced in development below.

Matsumoto: Conventional catalyst development relied heavily on the experimenter's experience and intuition, and it was not uncommon for it to take over five years to create a single new material. While the technological impact after success was massive, the road to get there was simply too long. This made it difficult to decide how many human resources and hours should be invested.

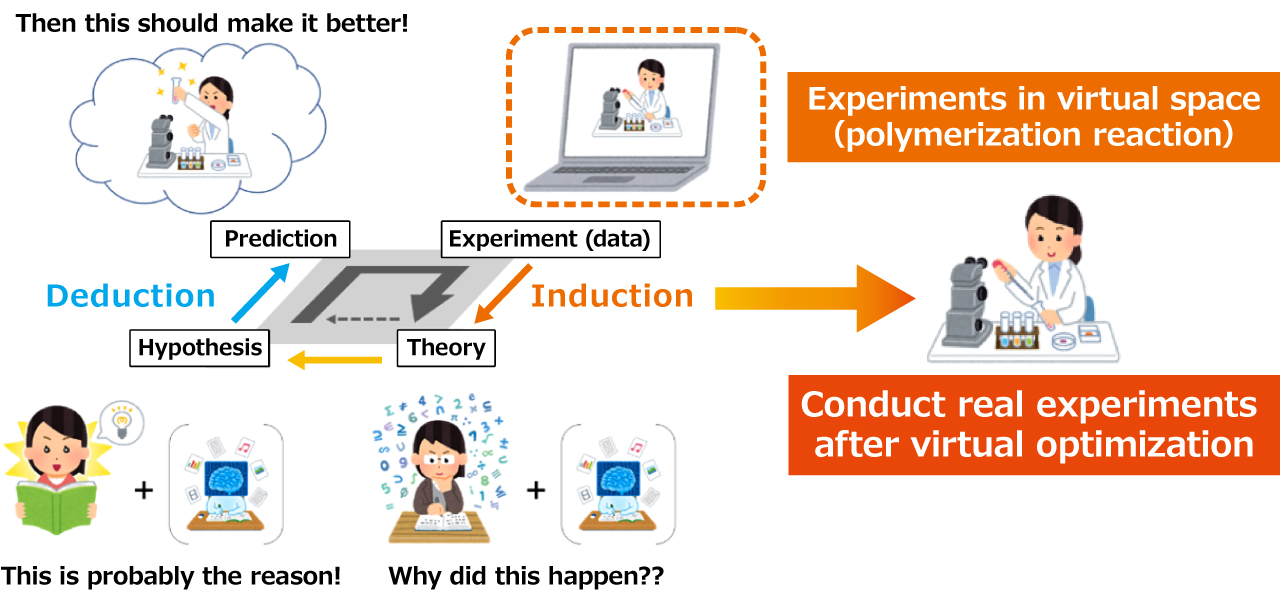

Research and development repeats a cycle of theory, hypothesis, prediction, and then experiments; but the experiment stage in particular requires a significant amount of time.

This led to a focus on experiments in virtual spaces on computers. This environment precisely recreates molecular structures and movements based on the laws of physics, enabling the calculation of molecular-level phenomena occurring in actual reactors, which allows us to predict processes in just a few hours/days which normally took many days.

Furthermore, by combining this with AI technology, it is anticipated that we will be able to identify patterns and trends difficult for humans to detect from vast simulation data. This will enable the prediction of optimal catalyst compositions, significantly enhancing the efficiency and accuracy of research and development.

Development of Simulation Technology through Industry-Academia Collaboration

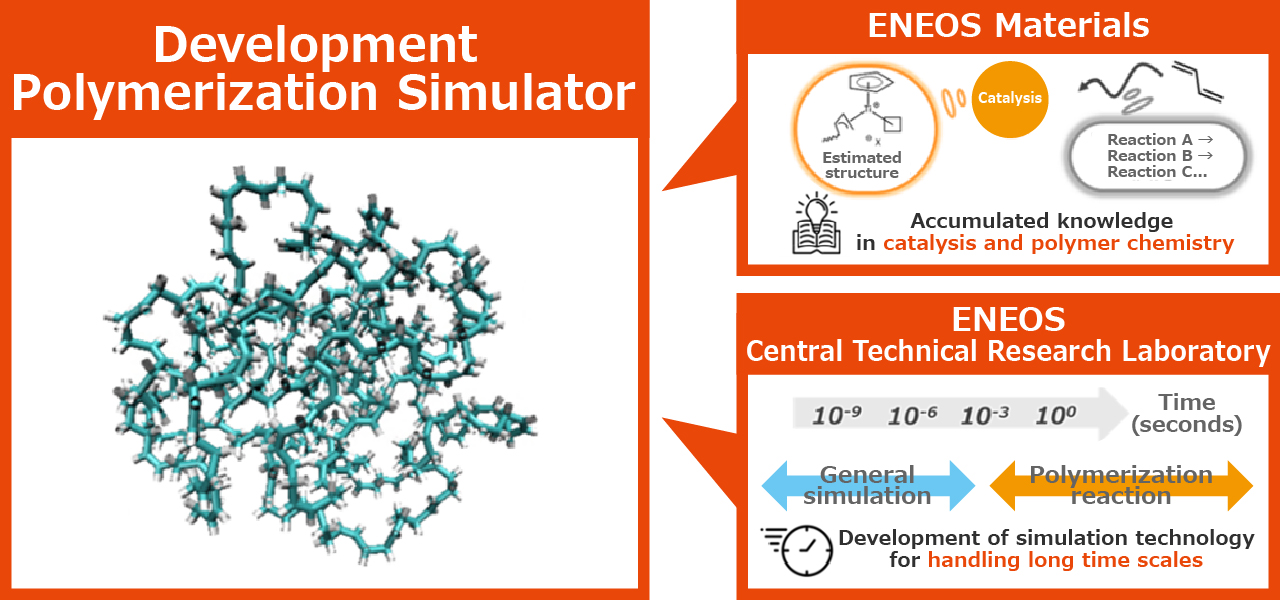

A project was started in 2023 with the aim of realizing a new research and development approach by combining ENEOS Materials' expertise in rubber synthesis cultivated over many years with molecular simulation technology which ENEOS Central Technical Research Laboratory specializes in. The addition of the Institute of Innovation for Future Society of Nagoya, which has its own unique molecular simulation technology, further advanced the research by combining the knowledge and technologies of all three parties.

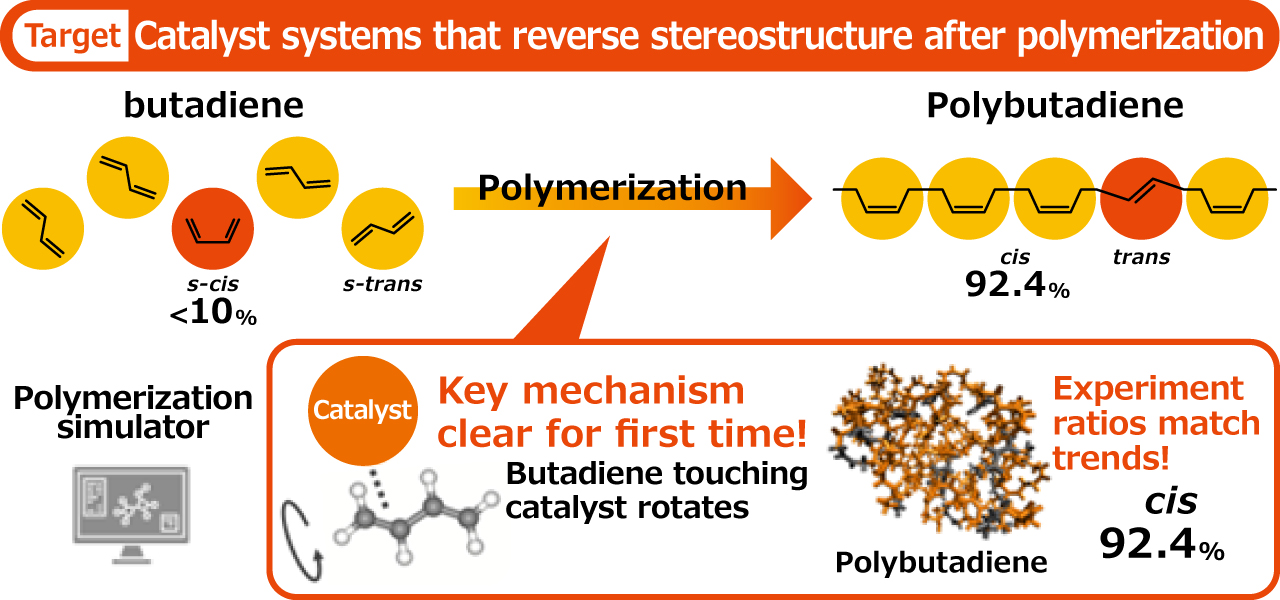

The molecular simulator currently under development is a tool that reproduces interactions between catalysts and butadiene at the molecular level, predicting what polybutadiene structures form under specific conditions. This enables the investigation of optimal catalyst combinations on a computer before conducting actual experiments, significantly reducing research and development time and costs. It also visualizes the molecular reaction processes that are normally invisible in experiments, leading to new discoveries.

After numerous adjustments and verifications, ENEOS Materials finally succeeded in developing a simulator in 2024 that could reproduce laboratory experimental results with high precision on a computer. As an unexpected outcome, detailed analysis of the simulation data led to the discovery of a new mechanism for polymerization reactions that had not been clear until now: the key factor for rubber molecules to bond in a specific direction. Hatamiya gives his remarks about this below.

Hatamiya: Computational chemistry approaches to polymerization reactions were considered extremely difficult. We had no clue what computational methods to adopt and what to develop as new functions to contribute to actual projects. At the beginning of our efforts, we struggled to accurately reproduce the actual polymerization phenomena, but based on Matsumoto's advice from his experiences, we worked on expanding functionality and finally succeeded in developing a practical prototype.

Prospects for the Development of Next-Generation Rubber Materials

High-cis BR, a synthetic rubber material manufactured and sold by ENEOS Materials, was selected for this research as its subject. High-cis BR is a rubber synthesized from butadiene, characterized by its cis-configuration where molecules are arranged in a regular, unidirectional pattern. This molecular arrangement allows for both excellent elasticity and abrasion resistance, making it an important industrial material widely used as the main component in vehicle tires.

Until now, the ENEOS group has focused on basic verification and accuracy improvement of developed molecular simulation technology, but starting in fiscal year 2025, it plans to apply this simulation technology to actual product development. Specific targets include developing rubber materials for tires that improve fuel efficiency, industrial rubber parts that realize longer service life, and next-generation rubber materials that reduce environmental impact. By leveraging simulation technology, ENEOS Materials expects to gain detailed insights into previously unobservable molecular-level behavior, enabling the efficient and precise design of rubber materials with properties tailored to specific objectives.

Going forward, the ENEOS Group will continue to engage in a wide range of collaborations to develop diverse material technologies that contribute to people's lives.