The Future Pioneered by ENEOS: Advanced Projects & Procurement Management in the ENEOS Group

The ENEOS Group is working to quickly improve investment efficiency as it aims to transform its management into a leaner structure capable of flexibly adapting to a non-continuous business environment. It is accelerating investments in large-scale energy plants and other projects, while also rigorously verifying the profitability of these projects and reconsidering less efficient ones. In this three-part series, we asked Someya Yoshiyuki, Chief Project and Procurement Officer (CPPO) who spearheads project management and procurement, about the advancement of Group-wide management, including the project gate system and procurement networks.

Part 2: Project Management utilizing the Gate System

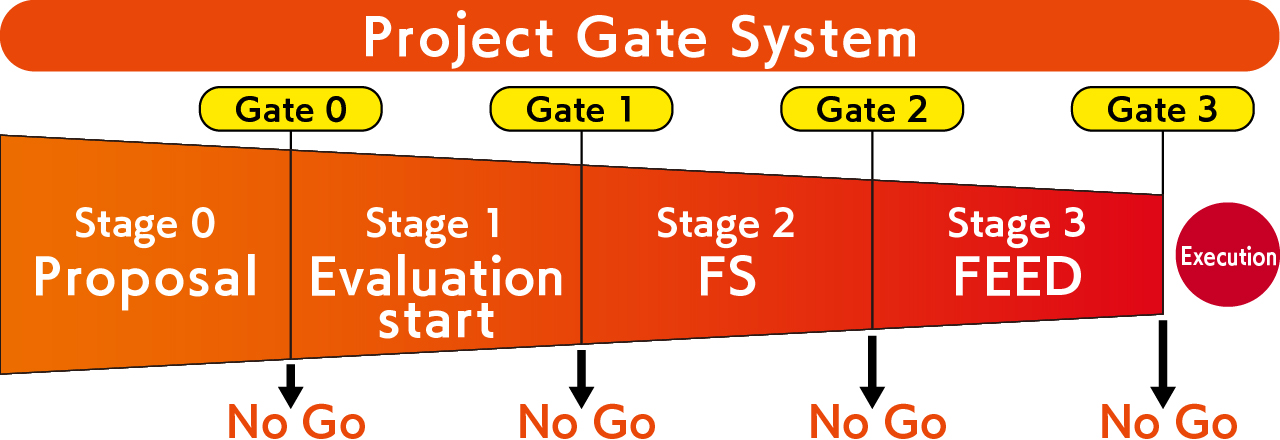

Dividing a project into some stages according to progress and conducting gate reviews at each stage; Terminating it early if profitability is not expected

――How does the ENEOS Group currently execute projects?

Someya: Each operating company has established its own procedures for executing projects. The ENEOS Group has established operational guidelines for investments, including in other companies’ projects, M&A, and in-house capital investments. With the exception of special cases, after a project is proposed, it goes through the following stages: a stage for initial feasibility study; a stage to decide whether to proceed with the project after evaluating feasibility; a stage to begin basic design; a stage to perform detailed engineering design and carry out procurement and construction work; and finally, a stage for commissioning (performance verification and trial operation) and operation. Gate reviews are conducted between each of these stages to determine whether the project can proceed to the next stage. Some projects may be terminated early as “No Go” if projected earnings are unlikely to be achieved. Project durations vary widely, ranging from those completed within a few years to those where basic design alone takes over a year. Projects have become increasingly complex in recent years, leading to longer timelines. What might have taken months in the past now often requires a year or more.

Feasibility Study (FS): Investigation and evaluation to confirm the project’s feasibility

Front End Engineering Design (FEED): Basic design carried out after feasibility is confirmed in the FS stage

――Can you tell us about the ENEOS Group’s project governance, which forms the basis for such project management?

Someya: The term “governance” may sound complex, but essentially, project governance is the system for how the ENEOS Group manages and supervises projects to achieve their objectives. The foundation is the gate system that I mentioned earlier, along with the investment reappraisal process that verifies whether the project progressed and was completed as planned. Our fundamental approach is “Trust, and Verify.” We thoroughly verify progress through systems like the gate system. In addition, we clearly define the deliverables required at each gate for verification. Therefore, I am confident that we have established a system that enables transparent and consistent decision-making regarding whether to proceed with or terminate a project. At the same time, within investment reappraisal, we share what went well in the project and what needs improvement, designing a system that drives the PDCA cycle. Major global oil companies also have these kinds of systems in place. We ensure that the departments executing projects thoroughly adhere to the established rules, advancing projects worldwide using the same methods and mindset. What we’re doing now at the ENEOS Group is essentially the same as what the aforementioned global capital companies are doing.

――How has the actual operation of the gate system been going?

Someya: To recap, the project gate system divides the project into multiple stages, conducting gate reviews between each stage to determine whether it’s a “Go” or “No Go.” We have set 14 evaluation criteria (elements) that serve as benchmarks for business and technical aspects, and each gate checks how well these items are met. Of course, many of these criteria may not be achievable in the early stages, but minimum standards that must be met at each gate have been established. We conduct various screenings from the early stages to identify risks, which helps prevent future problems, and if any changes occur, they are brought to the table at the next gate. In fact, since introducing the gate system, we’ve seen an increase in cases where inefficient projects are terminated midway. Some projects are also terminated during the initial evaluation phase. As the number of evaluations increases, we have to utilize resources not only internally but also from external engineering firms, so the decision to terminate early frees up these resources and builds trust with external partners. At the same time, since each operating company previously managed projects according to their own systems, there were initial concerns that the gate system was too detailed or would reduce operational efficiency. However, there have been more positive comments recently, such as, “While it does require extra effort, having this kind of system allows us to identify project risks earlier, which is helpful.” The gate system needs to be adapted according to the business environment and the status of project implementation, and we intend to continue updating it collaboratively with each operating company going forward.

――You also conduct training to thoroughly instill this project management mindset within the company.

Someya: Yes, we started this training in FY2024. We conduct project-related training by inviting instructors from external organizations that evaluate the investment efficiency of global corporate projects. We also conducted training sessions for presidents of major operating companies, CxOs of ENEOS Holdings, and management at the senior executive level. In addition, we are rolling out rank-based training on how to manage large-scale projects and utilize the gate system, and we require all Group employees involved in projects to attend at least once. We also want to provide ongoing refresher training rather than a one-time session.

――You have also launched a new procurement network within the Procurement Department.

Someya: The ENEOS Group has a Group-wide procurement policy, and our major operating companies carry out procurement based on this policy. As one goal to ensure thorough procurement governance across the entire Group and pursue strategic procurement, we aim to visualize each company’s procurement status as our major operating companies and ENEOS Holdings collaborate through network activities. We want to visualize the current status of procurement based on the ENEOS Group Procurement Policy—for example, whether sustainable procurement (CSR procurement) is being achieved across the entire ENEOS Group supply chain—and provide feedback to each company. In terms of strategic procurement, we want to share the best practices of each company, including management methods, to enhance the competitiveness of the entire Group.

――Do you feel like you’re making progress with the procurement network?

Someya: I feel that we are making steady progress. We have thoroughly implemented the concept of CSR procurement (Reference: Learning Materials ~ Getting Started with CSR Procurement ~ | About the ENEOS Group | ENEOS Holdings [in Japanese]), mapped improvement points in the procurement processes of major operating companies, and strengthened governance. Some examples of best practices have already been shared across the Group, and training is underway at other companies for their implementation. We’re also seeing examples of cost optimization through changing purchasing methods, such as adopting better approaches when available. As with projects, we’ve only just taken the first step, and I don’t believe we’ve reached a point where each operating company is collaborating with a sense of agreement. I would like us to focus on eliminating disparities between companies, ensuring strong horizontal integration, and moving forward in a positive direction as a unified Group.

――Thank you. Next time, we will discuss future developments of interest.

■ Summary

This article delved into the ENEOS Group’s project and procurement management, including the gate system that divides projects into multiple stages with gate reviews between each stage, and the visualization of group procurement information through the procurement network. The gate system and procurement network are beginning to gain traction. The next part will discuss what goals lie ahead, including new initiatives currently in preparation. Don’t miss it!

→Continued in Part 3: The Future Pioneered by ENEOS: Advanced Projects & Procurement Management in the ENEOS Group | ENEOSWAYS | ENEOS Holdings