Prevention of Environmental Pollution

Basic Approach

In addition to complying with relevant laws and regulations, the ENEOS Group works to maintain and conserve natural resources such as water, soil, and the atmosphere by curbing the further release of environmental pollutants, effectively utilizing water resources, and other measures.

To prevent environmental pollution, we continuously work to mitigate risks by improving our facilities and conducting emergency response and other training drills covering items identified as serious concerns from an environmental perspective through the environmental management system (EMS) of each Group company.

Structure

For information on our structure (EMS), see Environmental Management.

Major Initiatives

Establishment of and Compliance with Targets and Voluntary Standards More Rigorous than Statutory Requirements

ENEOS’s refineries and plants voluntarily conclude pollution prevention agreements with local governments. In these agreements, we have set targets for the avoidance and reduction of environmental pollution and the quality of wastewater that are more rigorous than those stipulated by laws and regulations, and we comply with them.

In fiscal 2024, there were no serious leaks or discharges.

Prevention of Air Pollution

- For information about , see the Editorial Policy.

Reducing SOx Emissions

Sulfur oxides (SOx), which are known to cause acid rain, are released into the atmosphere mainly as a component of exhaust gases from combustion facilities.

The Group carries out measures such as using fuels with low sulfur content, removing SOx using flue gas desulfurizers, and managing emissions using voluntary standards.

SOx emissions in fiscal 2024 totaled 8 thousand tonnes, a decrease from the previous fiscal year.

Reducing NOx Emissions

Nitrogen oxides (NOx), like SOx, are known to cause acid rain and are released into the atmosphere mainly as a component of exhaust gases from combustion facilities.

The Group carries out measures such as using low-NOx boilers at combustion facilities, removing NOx using flue gas denitrizers, and managing emissions using voluntary standards.

NOx emissions in fiscal 2024 totaled 12 thousand tonnes, about the same as the previous fiscal year.

Reducing VOC Emissions

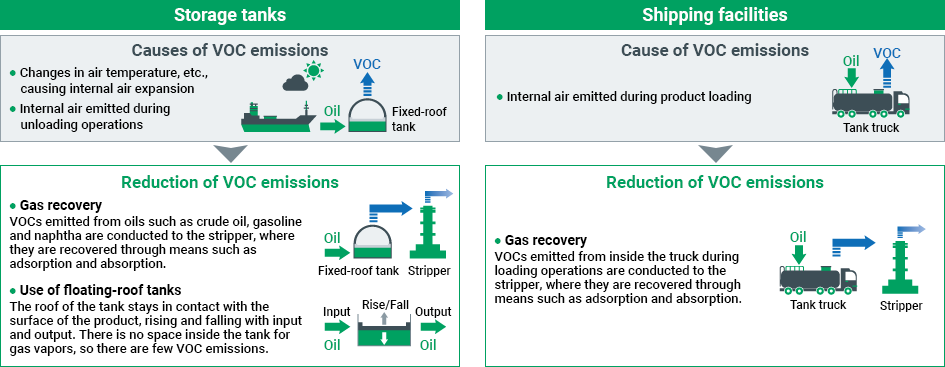

Volatile organic compounds (VOCs), which are thought to produce photochemical oxidants through a photochemical smog reaction with NOx and ultraviolet rays from sunlight, are released from places such as storage facilities for petroleum products.

The Group has installed VOC recovery equipment in storage facilities and truck loading facilities.

VOC emissions in fiscal 2024 totaled 11 thousand tonnes, about the same as the previous fiscal year.

VOC Recovery

Volatile organic compounds (VOCs) containing hydrocarbons are released into the air whenever gasoline is pumped from tank trucks into storage tanks at service stations. These VOCs are not only a source of photochemical oxidants, but also cause irritating odors in neighboring communities and can adversely affect the health of both customers and employees.

Therefore, ENEOS has installed recovery equipment on the ventilation ducts of service station storage tanks, which enables tank trucks to recover these VOCs so that they are not released into the atmosphere.

The ENEOS Group’s Kiire Terminal recovers, without releasing, the gases that have accumulated inside tankers when loading crude oil, and reuses the VOCs contained in these gases by absorbing them into the crude oil. Gases, including odor-causing ones, that are not absorbed are broken down.

The Group was the first in the world to implement this mechanism. This technology is contributing to the advancement of environmental conservation measures and the effective utilization of energy.

VOC Emissions and Reduction Measures at Refineries

Effective Utilization of Water Resources and Preventing Water Pollution

- For information about , see the Editorial Policy.

Effective Utilization of Water Resources

Each of the Group’s principal business sites has established and operates an environmental management system (EMS), which they use to appropriately assess and address environmental impacts concerning water usage.

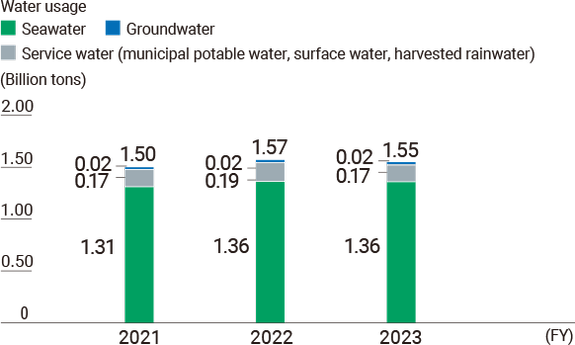

Water Usage

The Group uses water for purposes such as operating and cooling power generation facilities at refineries and smelters. Approximately 88% of this water is seawater.

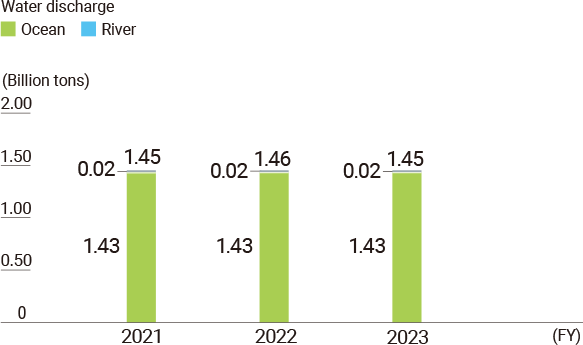

In fiscal 2024, the volume of water used was 1.51 billion tonnes, and the water discharge volume was 1.37 billion tonnes.

The ENEOS Group recycles approximately 97% of the cooling water, which accounts for most of the water usage, at its refineries. To reduce the amount of water used, smelters that use seawater for cooling have partially switched to recycled water.

ENEOS Group Water Discharge Volume

- Notes:

- The amount of wastewater discharged into groundwater and wells, discharged into off-site water treatment facilities, and discharged for water use and other use are all zero.

- Figures for each item have been rounded. As a result, the sum of the figures may not match the total.

- For detailed data, see Data.

Response to Water Risks

The Group uses tools such as the Aqueduct water risk mapping tool from the World Resources Institute (WRI) to verify whether our manufacturing sites are in areas of elevated water risk.

In fiscal 2021, we assessed water risks at our manufacturing sites (21 sites) and confirmed that there are no high-risk sites. In fiscal 2022, we reassessed 20 of these sites and newly assessed seven major overseas manufacturing sites.

As a result, PT. JX Nippon Oil & Energy Lubricants Indonesia was assessed as high risk in terms of “coastal nutrition potential” of water quality. However, the impact on water quality has been reduced at the plant because the environmental impact on the water quality of the discharge destination has been identified and a management system based on ISO 14001, including compliance with local regulatory standards, has been put into place. We do not expect any major impact that will affect the operation of the plant.

With efforts to conserve and manage water resources gaining attention worldwide, going forward, we will review the results of risk assessments every three years. In addition, in the event that new high-risk indicators are identified due to the expansion of the scope of data or other factors, we will obtain detailed information from external organizations and assess the impacts on our operations.

Reducing the Release of Water Pollutants

The Group manages and monitors pollutants in wastewater through regular maintenance of water treatment facilities based on voluntary standards that are more rigorous than laws, regulations, ordinances, and agreements, including Japan’s Water Pollution Prevention Act.

In fiscal 2024, there were no serious violations of laws or regulations concerning the prevention of water pollution and no oil spills or other serious incidents at our manufacturing sites.

Preventing Marine Pollution

For the marine transport of oil, the ENEOS Group is required to comply with the International Convention for the Prevention of Pollution from Ships (MARPOL), an international convention developed by the International Maritime Organization (IMO) that includes regulations for the prevention of environmental pollution from oil and the prohibition of waste discharge into oceans and seas.

In addition to fully complying with this convention, we take further steps to prevent marine pollution, such as taking incinerator ash as defined in the convention back to land for proper disposal rather than discharging it into the ocean.

ENEOS established a new manufacturing method and a shipment system for low-sulfur marine fuel in accordance with the introduction of worldwide environmental regulations by the IMO in January 2020.

Soil Contamination Countermeasures

ENEOS conducts regulatory-compliant surveys on land that it owns that has the potential for soil or groundwater contamination, focusing particular efforts on sites such as refineries, oil depots, and service stations, and also undertakes voluntary surveys at opportunities such as the decommissioning of facilities. If contamination is confirmed, appropriate remediation measures are implemented based on site-specific conditions.

In fiscal 2024, there were no instances of soil contamination at ENEOS properties.