Basic Approach

At the ENEOS Group, we work to fulfill our social responsibilities across the entire supply chain by cooperating with suppliers of raw materials, logistics companies, construction companies, sales companies and others involved in our business activities, while carrying out initiatives for compliance, environmental conservation, human rights and labor, and health and safety.

In accordance with this approach, we have established basic principles on procurement in the Group Code of Conduct and the Group Procurement Policy, based on which we are implementing a number of initiatives. Based on the Group Code of Conduct and the Group Procurement Policy, Group companies carry out their procurement activities in accordance with their business characteristics.

Excerpt from the Introduction of the ENEOS Group Code of Conduct

- 3.Applicable scope of the Code of Conduct

In principle, this Code of Conduct is applicable to all directors, officers and employees who work at ENEOS Holdings, Inc., and its subsidiaries. We also encourage companies that are part of our value chain to comply with this Code of Conduct. These companies include, but are not limited to, suppliers of raw materials, logistics companies, construction companies, and sales companies.

ENEOS Group Procurement Policy

All executives and employees of the ENEOS Group shall comply with this policy when they engage in procuring the goods and services necessary for business operations.

We also request that our suppliers understand this policy and guidelines and cooperate with us in following them.

- 1.Social Responsibility

The ENEOS Group will conduct procurement activities based on the ENEOS Group Code of Conduct, Human Rights Policy, and other policies in each sector. - 2.Selection of Business Partners

When selecting suppliers, the ENEOS Group will make fair and impartial judgments based on respect for human rights principles in Japan and overseas, and consideration for the environment, quality, and delivery times. - 3.Mutual Trust

The ENEOS Group emphasizes doing business with suppliers on an equal footing and aims to build mutually trusting relationships. - 4.Information Management

The ENEOS Group shall appropriately manage information obtained through its procurement activities.

Procurement Guidelines for Business Partners of Principal Operating Companies

- ENEOS

- ENEOS Materials(Available in Japanese only)

- ENEOS Power(Available in Japanese only)

- ENEOS Renewable Energy(Available in Japanese only)

Structure

For information about our structure, see ESG Management Structure.

Major Initiatives

CSR Procurement

The Group implements CSR procurement in cooperation with its suppliers. At principal operating companies, we request that suppliers implement initiatives related to compliance, environmental conservation, human rights and labor, and health and safety in contracts and other agreements that form the basis of purchasing transactions.

Based on the results of human rights due diligence and the Corporate Human Rights Benchmark (CHRB) assessment, we are working on “consideration of human rights factors in supplier selection.” For details, see Human Rights Due Diligence.

Additionally, to ensure responsible procurement, employees in charge of procurement receive training to raise their awareness of the ENEOS Group Philosophy, the ENEOS Group Code of Conduct, the ENEOS Group Procurement Policy, and applicable laws and regulations.

Specific Actions to Support Living Wages for Suppliers

The procurement guidelines contain provisions for setting wages that at least meet minimum wage standards and payment of premium wages (overtime and holidays). All Group companies are required to comply with these guidelines.

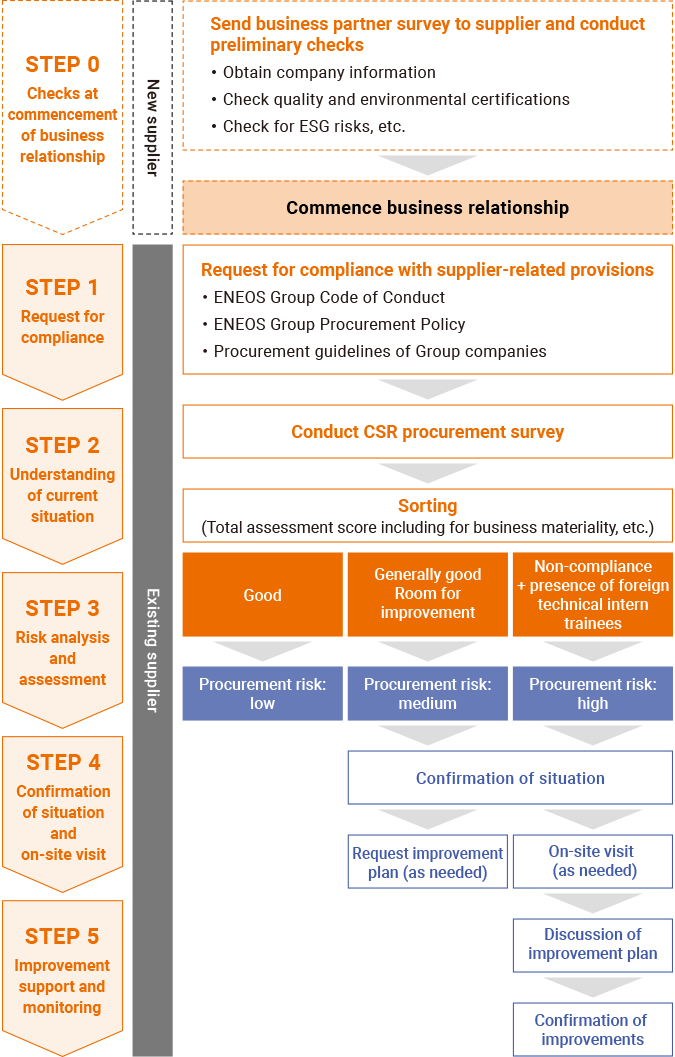

CSR Procurement Workflow at ENEOS

Checks at Commencement of Business Relationships with New Suppliers

When selecting a new supplier, ENEOS first confirms that the supplier has no relationship with anti-social forces. In addition to confirming the supplier’s financial position and performance, we conduct a comprehensive risk assessment by asking the supplier to complete our business partner survey, which includes items related to quality and environmental certifications, as well as ESG risks.

CSR Procurement Survey of Suppliers

ENEOS conducts CSR procurement surveys of its main suppliers to identify potential risks in the supply chain.

Through this survey, we assess risks related to compliance, the environment, human rights and labor, and health and safety. For suppliers whose responses indicate the presence of risks, we conduct detailed checks.

In fiscal 2024, we revised the CSR procurement survey based on past survey results and the societal situation. In the human rights and labor category, we added questions regarding foreign technical intern training systems, and in the environment category, we expanded questions related to carbon footprint. By diving deeper into specific themes, we aim to better identify high-risk suppliers.

Additionally, we held advance briefing sessions for the suppliers to be surveyed, which were attended by about 80 companies. By explaining the importance of CSR procurement as well as the purpose and content of the CSR procurement survey, we achieved a response rate of over 90%.

CSR Procurement Survey Process

- 1.Selection of main suppliers

Considering the continuity and impact of transactions, we select main suppliers based on criteria such as the importance of the business partner in terms of transaction amount, substitutability and sector, as well as past CSR procurement survey results, incident history, and ESG risks. In fiscal 2024, only domestic suppliers were subject to the survey. - 2.Implementation of CSR procurement survey

ENEOS holds briefings on the importance of CSR procurement and its ESG initiatives with the selected suppliers, and then asks them to respond to the CSR procurement survey. Referencing the RBA1 VAP2 audit standards, the survey consists of 73 questions covering eight categories: compliance and fair and equitable transactions, provision of products and services, information management, supply chain, environment, human rights and labor, health and safety, and dialogue and cooperation with local communities (see the table below). Items are evaluated after being classified into two categories: items related to the internal management structure, such as the clear documentation of policies on compliance and human rights protection, the enforcement of compliance, and the identification of those responsible for reducing environmental impact, and items related to the status of activities, mainly those that can be quantified, such as the volumes of contaminated materials discharged and the number of occupational injuries.- 1Responsible Business Alliance. An industry coalition for ensuring responsible conduct in global supply chains within the electronics industry established in 2004. The RBA established the RBA Code of Conduct to ensure that working environments are safe, that workers are treated with respect and dignity, and that companies are environmentally conscious and responsible in their business activities. RBA member companies are required to abide by the RBA Code of Conduct. As of June 2025, the RBA has more than 250 member companies.

- 2The Validated Assessment Program (VAP) is an audit program in which a third-party auditor confirms compliance with the RBA Code of Conduct. VAP audits are conducted to ascertain whether compliance requirements are met in accordance with the VAP standards, which consist of labor, health and safety, environmental, ethics, and supply chain management.

- 3.Tabulation of survey responses and risk assessment

Survey responses are tabulated and scores are calculated for each question, enabling us to assess the management structure and status of activities of the supplier. - 4.Improvement support and monitoring

We ask suppliers for which risks have been identified to submit improvement plans and we monitor the progress of their improvements.

CSR Procurement Survey Composition (Total of 73 Questions)

| Category | Item | Survey items | ||

|---|---|---|---|---|

| Compliance and fair and equitable transactions |

|

12 questions |

|

10 |

|

2 | |||

| Provision of products and services | Appropriate provision of products and services | 5 questions |

|

3 |

|

2 | |||

| Information management | Appropriate information management and information disclosure | 4 questions |

|

1 |

|

3 | |||

| Supply chain | Supply chain management and supervision | 1 question |

|

1 |

|

- | |||

| Environment |

|

19 questions |

|

6 |

|

13 | |||

| Human rights and labor |

|

23 questions |

|

5 |

|

18 | |||

| Health and safety | Ensuring safety and health enhancement | 8 questions |

|

3 |

|

5 | |||

| Dialogue and cooperation with local communities | Dialogue and cooperation with local communities | 1 question |

|

- |

|

1 | |||

Risk Analysis and Assessment

Supplier responses to the CSR procurement survey are analyzed and assessed according to four levels of criteria.

The following table contains a summary of assessment criteria and ENEOS’s response to the assessment findings.

Suppliers who received the lowest assessment of “non-compliant” or those considered to pose potential risks are identified and subject to follow-up.

From fiscal 2022, suppliers who responded that they accept foreign technical intern trainees are also subject to follow-up.

Risk Assessment Classification and Response

| Assessment | ENEOS’s response | |

|---|---|---|

| Good | Overall, sufficient measures are being implemented. | Each supplier receives a report on the survey results. Assessment results, including areas for improvement, are communicated to suppliers and information, such as the assumed risks for each category and information on relevant international guidelines, is provided. |

| Generally good | Measures are being implemented for a relatively large number of items; risk is low. | |

| Room for improvement | Measures are not being implemented for some items; risk is moderate. | |

| Non-compliant | Items such as receiving adverse dispositions from government bodies, failing to confirm the facts and implement measures to prevent recurrence of violations, and the occurrence of serious occupational injuries are identified; risk is extremely high. | High-risk supplier. In addition to the response above, issue request for improvement and conduct monitoring, along with individual follow-up. |

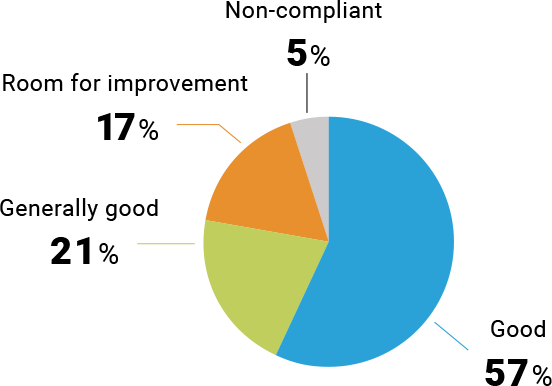

CSR Procurement Survey Results

Since fiscal 2018, the Group has selected a total of 1,748 suppliers to complete the CSR procurement survey, with responses received from 1,651.

We provide feedback to suppliers based on their survey responses and request improvements or corrective actions where necessary. Approximately 80% of suppliers who completed the survey were assessed as “good” or “generally good,” indicating that there are no issues regarding the human rights risks that we closely monitor within our supply chain (child labor and forced labor).

CSR Procurement Survey Results (total of 1,651 suppliers)

Improvement Support and Monitoring

At ENEOS, we have been conducting on-site supplier surveys since fiscal 2023 with the aim of reducing supplier risks and expanding communication opportunities. Based on the results of CSR procurement surveys, we visit suppliers who have been assessed as “non-compliant” or those considered to pose potential risks and conduct on-site inspections, document reviews, interviews, and other activities to investigate their management systems and initiatives related to CSR procurement. The items for confirmation were developed with reference to the RBA VAP audit standards.

As a result of on-site supplier surveys, we have classified items that need to be improved into “critical non-compliance” and “other non-compliance” and requested corrective measures from suppliers (see the table below). For suppliers with an assessment of “critical non-compliance,” we discuss the direction of corrective action, which leads to support for improvement.

In fiscal 2023, we visited three companies and ascertained that there were no issues. We plan to continue conducting these on-site supplier surveys, not only to confirm the status of responses, but also as opportunities to communicate directly with suppliers.

Classification of Non-Compliance and Deadlines for Corrective Action

| Classification of non-compliance | Deadline for submission of corrective action | Approval of corrective action | Completion of corrective action | Applicable items (examples) |

|---|---|---|---|---|

| Critical non-compliance |

Within 1 week of discovery | Within 10 days of discovery | Within 90 days | Violations of human and labor rights (forced labor, child labor, discrimination, etc.), inhumane treatment, serious occupational injuries, environmental damage that has a significant impact on communities, etc. |

| Other non-compliance |

Within 3 weeks of receipt of the survey report | Within 6 weeks of receipt of the survey report | Within 180 days of receipt of the survey report | Other insufficient initiatives in light of the Group’s Code of Conduct and procurement guidelines. |

Initiatives for Foreign Technical Intern Trainees

Since fiscal 2024, we have expanded the questions in the CSR procurement survey for suppliers employing foreign technical intern trainees to confirm that there are no issues with the legal compliance and employment conditions of the supervising organization or the host company.

Training and Awareness Activities

Supplier Briefings

ENEOS holds supplier briefings for suppliers subject to the CSR procurement survey to promote understanding of the purpose and content of the survey and to raise awareness and understanding of CSR procurement based on ESG risks.

In fiscal 2024, approximately 80 companies participated. In the first part of the briefing, we shared examples of corporate incidents related to human rights and the environment (social issues) to help participants understand the importance of CSR procurement. We also conveyed our intent to promote ESG management, which the Group aims for, together with our suppliers. In the latter part, we explained the purpose and content of the CSR procurement survey.

In addition, with regard to human rights, which has become an increasingly important social issue, we explained the ENEOS Group Human Rights Policy, which is the Group’s basic approach to human rights, and our human rights initiatives, and requested suppliers’ understanding of and compliance with the policy.

Providing Tools to Suppliers to Support ESG Initiatives

The Group has been providing tools to suppliers to support their ESG initiatives since fiscal 2025, aimed at promoting suppliers’ voluntary action regarding ESG.

Based on the results of the CSR procurement survey conducted in fiscal 2024 and societal demands in procurement, we selected four themes: CSR procurement, human rights, CO2 emissions calculation, and circular economy.

For information on these support tools, please refer to the following link.

Learning materials

- Intro to CSR procurement (video)

- Human rights initiatives

- CO2 emissions calculation

- Circular economy initiatives for contributing to the development of a recycling-oriented society

- Learning materials: Intro to CSR procurement(Available in Japanese only)

Training for Employees Involved in Procurement

In order to promote responsible procurement throughout our supply chains, we believe it is important for the Group’s employees to understand CSR procurement.

In fiscal 2024, ENEOS held a study session for procurement personnel in preparation for on-site supplier surveys to be conducted in the following fiscal year. The participants learned about the content of the CSR procurement survey and the on-site supplier surveys.

Membership in Sedex and EcoVadis

In fiscal 2019, ENEOS became a member of both Sedex and EcoVadis, ratings providers for supply chain sustainability.

Confronting the Issue of Conflict Minerals

The Group conducts procurement activities based on the Group Code of Conduct, which stipulates that we will not engage in transactions that lead to the prolongation of conflicts, human rights abuses, or inhumane acts.

Regarding the handling of conflict minerals1, in the third round of human rights due diligence, conducted in fiscal 2023, we confirmed that there is no handling of conflict minerals (tin, tantalum, tungsten, gold) within the business areas of the principal operating companies2.

- 1“Conflict minerals” is the general term for minerals that are mined (illegally, in most cases) in conflict-affected regions, providing a source of funds for local armed groups. The use of these minerals may lead to increasing human rights abuses and inhumane acts.

- 2Oil and gas business (including the upstream areas of ENEOS Xplora), lubricants and renewable energy businesses (ENEOS Renewable Energy), and high performance materials business (ENEOS Materials)

Initiatives with Distribution Companies

ENEOS shares its environmental and safety policies and targets for each fiscal year with the contract transport providers responsible for transporting its products in an effort to increase awareness of the environment and safety.

We work with vehicle manufacturers to hold the Ecodrive & Safety Workshop for drivers about 10 times a year, and also encourage transport companies to participate in the Ecodrive Activity Concours, hosted by an external organization, thereby promoting eco-driving. We hold meetings of safety managers with transport companies in each region, where we share best practices from each company and actively carry out activities to raise safety awareness.

ENEOS Materials outsources all of its logistics operations to logistics companies. It holds quarterly conferences with its logistics contractors to share logistics issues related to quality, safety, and the environment, and strengthen cooperation by managing the progress of improvement activities. To foster and instill safety awareness in each and every worker, ENEOS Materials works in collaboration with its logistics contractors to ensure that work risks are identified and education and training are carried out appropriately.

Through our initiatives to achieve sustainable logistics and distribution, we seek to increase the productivity of the entire supply chain, thus contributing to the fulfillment of our responsibility to provide a stable supply of energy and materials.

Support for the White Logistics Movement

ENEOS has supported the White Logistics movement since 2019 and ENEOS Materials has supported the movement since 2023. This movement seeks to improve the productivity of truck transport, increase the efficiency of logistics and distribution, and ensure comfortable work environments for women and seniors. Both companies have submitted voluntary action declarations under this movement.

In addition, based on the revision of various laws and regulations aimed at reforming workstyles and improving logistics efficiency, we are responding to the associated “2024 logistics issues.”

In March 2018, ENEOS revised transport fees to improve the treatment of drivers and started early efforts to shorten working hours by increasing the number of vehicles and personnel. Furthermore, by revising its transport fees in April 2025, following on from the previous year, ENEOS is responding flexibly to the recent upward trend in wages.

ENEOS’s Voluntary Action Declaration and Initiatives

- 1.Proposals and cooperation for improving logistics and distribution

- 2.Separation of trunk route transport and collection/delivery transport

- 3.Encouraging use of expressways

- 4.Deliveries that avoid peak rush hour

- 5.Continuation of fuel surcharges

- 6.Suspending or stopping transport operations during extreme weather